Bag filters are an essential part of many industrial processes, providing effective filtration for a wide range of materials. But what exactly can bag filters move? In this guide, we’ll explore the capabilities of bag filters, how they work, and the benefits they offer. Filter Sciences is a leading provider of bag filters and filtration solutions, so you can trust our expertise in this field.

Solid Particle Filtration

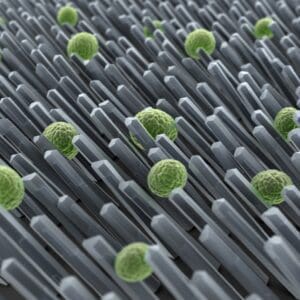

One of the most common uses for bag filters is the removal of solid particles from liquids and gasses. Bag filters can remove particles ranging in size from a few microns up to several millimeters, depending on the filter media and design. These particles can include dust, sand, rust, and other contaminants that can clog machinery, damage equipment, or cause product defects. Bag filters can be used in a variety of industries, including food and beverage, pharmaceuticals, and manufacturing.

In the food and beverage industry, bag filters are used to remove impurities from ingredients such as flour, sugar, and spices, ensuring that the final product is free of contaminants. Bag filters can also be used to filter the water used in the production process, removing any sediment or particulate matter that could affect the taste or quality of the product.

In the pharmaceutical industry, bag filters are used to remove particles from drugs and other products, ensuring that they meet the strict purity and safety standards required by regulatory bodies. Bag filters can be used in both the manufacturing process and in research and development labs, where they are used to filter air and gasses to maintain a sterile environment.

In manufacturing, bag filters are used to remove particles from lubricants, coolants, and other fluids used in the production process. This can help prevent equipment failure, reduce downtime, and improve product quality.

Liquid Contamination Removal

Bag filters can also be used to remove liquid contaminants from a variety of liquids, including water, oils, and chemicals. These contaminants can include dirt, debris, and other impurities that can affect the performance of machinery or products. Bag filters can remove contaminants down to a few microns in size, depending on the filter media and design.

In the water treatment industry, bag filters are used to remove sediment, sand, and other particles from water, improving its clarity and purity. Bag filters can also be used to remove chlorine, bacteria, and other contaminants from drinking water and industrial wastewater.

In the oil and gas industry, bag filters are used to remove impurities from crude oil, refined oil, and other products, ensuring that they meet the purity standards required for use in various applications. Bag filters can also be used to filter the water used in hydraulic fracturing, removing impurities that can damage equipment and reduce efficiency.

In the chemical industry, bag filters are used to remove contaminants from various chemicals and solvents, ensuring that they meet the purity standards required for use in various applications. Bag filters can also be used to remove impurities from liquid chemicals used in the manufacturing process, improving product quality and safety.

Gas and Vapor Filtration

Bag filters can also be used to filter gasses and vapors, removing impurities and ensuring that they meet the required purity standards. Bag filters can remove particles and contaminants down to a few microns in size, depending on the filter media and design.

In the automotive industry, bag filters are used to remove particulate matter from exhaust gasses, reducing emissions and improving air quality. Bag filters can also be used to filter the air in manufacturing facilities, removing dust and other particles from the air to create a cleaner and safer working environment. In the pharmaceutical industry, bag filters are used to filter air and gasses to maintain a sterile environment in research and development labs and manufacturing facilities.

Benefits of Using Bag Filters

There are several benefits to using bag filters in industrial processes. One of the main advantages is their versatility, as bag filters can be used for a wide range of applications and can handle a variety of materials. They are also highly effective at removing particles and contaminants, improving product quality, and extending the life of machinery and equipment. Additionally, bag filters are easy to install and maintain, with minimal downtime required for replacement and cleaning.

Another benefit of using bag filters is their cost-effectiveness. Bag filters are typically less expensive than other types of filtration systems, making them a cost-effective solution for many industrial applications. They are also highly efficient, with a high dirt-holding capacity and low-pressure drop, meaning they can handle a large volume of material without requiring frequent replacement.

Bag filters are also environmentally friendly, as ours are made from stainless steel and are reusable. This makes them a sustainable option for companies looking to reduce their environmental impact.

Bag filters are a versatile and effective solution for a wide range of industrial applications. They can handle a variety of materials, including solid particles, liquid contaminants, and gasses and vapors, and are cost-effective, easy to install and maintain, and environmentally friendly. If you’re in need of a filtration system for your industrial process, contact Filter Sciences for more information on how bag filters can improve product quality, extend the life of your machinery and equipment, and reduce your environmental impact.

Contact Us