Here at Filter Sciences, we strive to provide only the highest quality, commercial-grade filtrations systems to remove particles and other contaminants from liquids to maintain safety and quality for our clients. One of the vital components of any industrial filtration system is the filter bag housing and the bag filter itself, which is used to filter solid particles from liquids. However, many operators and maintenance personnel have questions about bag filters, how they work, and the best practices for ensuring optimal filtration.

In this blog, we’ll share frequently asked questions we receive from clients about bag filters. Whether you’re ready for a quote or still need more information on the bag filter systems we offer at Filer Sciences, our team is always here to support your commercial filtration needs! Contact us today.

Q: What Is a Bag Filter and How Does It Work?

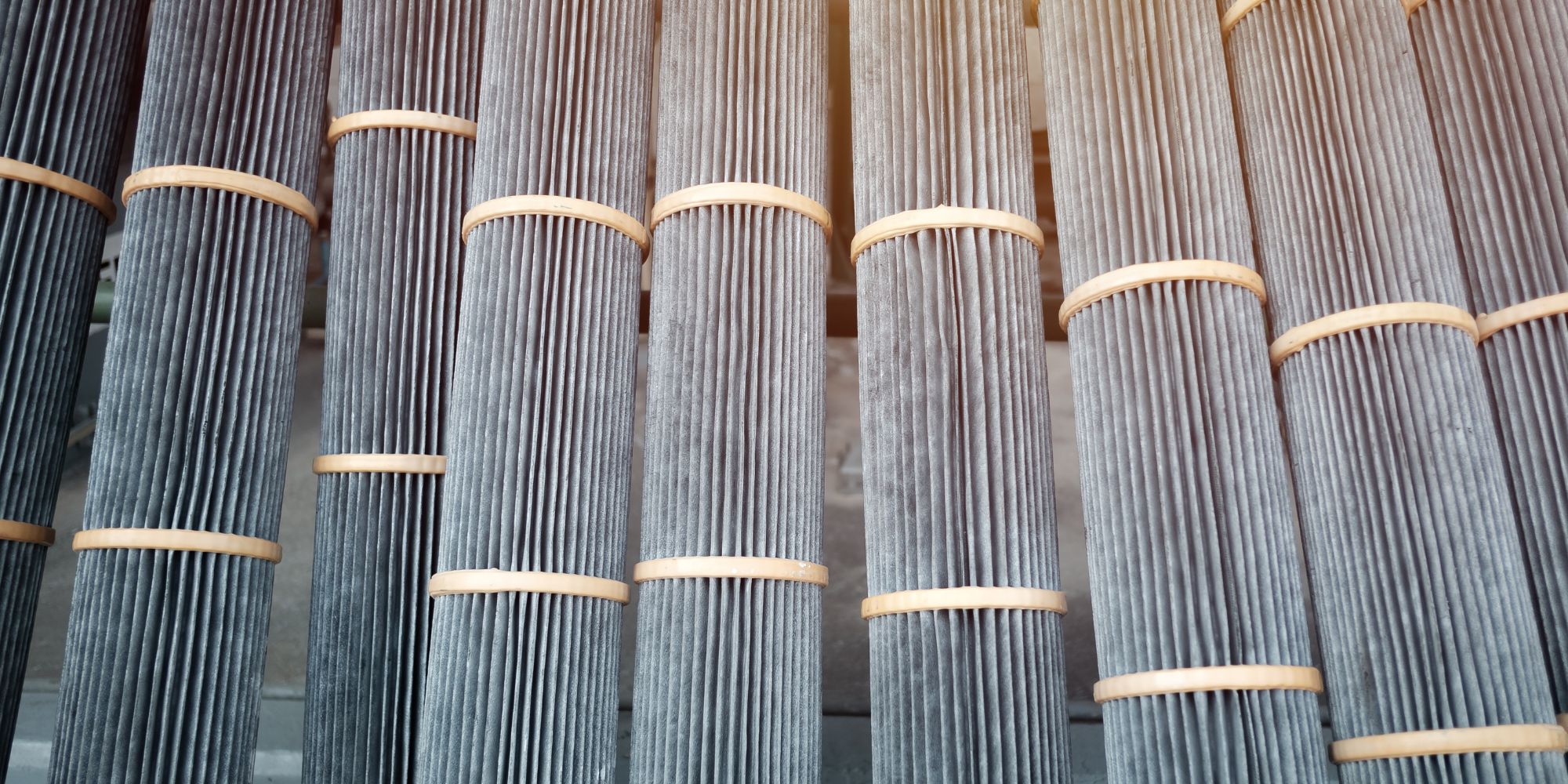

A: A filter bag housing is a cylindrical, replaceable filter bag made of various materials. Its basic function is to capture solid particles carried in liquids. The industrial process includes liquid entering the bag filtration housing and moving through the filter, where the bag filter is able to retain solid particles, allowing only clear liquid to pass through to the outlet. In simple terms, the bag filter works as a strainer to keep solid contaminants inside it.

Q: What Are the Different Types of Bag Filters?

A: The different types of bag filters include:

- Polyester, Polypropylene, Nylon, and other synthetic bag filters: Used to filter industrial liquids containing solid particles like oil, ink, chemicals, and paints. They are affordable and come in different micron ratings.

- High-temperature bag filters: Used to filter high-temperature liquids like hot oil, hot water, and other thermal liquids. These bag filters are made of special fibers and materials that can withstand high temperatures.

- Mesh bag filters: Used to filter liquids containing organic and inorganic materials that require fine filtration.

Q: How Do You Select the Right Bag Filter?

A: Selecting the right bag filter depends on the type of liquid particle size, operating temperature, and flow rate. Our team of filtration experts is always here to ensure questions about our bag filtration housings, including helping you determine the right bag filter for your application. A bag filter that is too fine may clog quickly and cause excessive pressure drop, while a bag filter that is too coarse may not capture all the contaminants and result in a reduction of product quality.

Q: How Often Should You Replace the Bag Filter?

A: The frequency of bag filter replacement depends on the operating conditions and type of liquid being filtered. For example, highly contaminated liquids with a fast flow rate may require more frequent bag filter changes than less contaminated liquids. On the other hand, if you’re using a filter bag housing for a liquid with a lower flow rate and fewer particles, you won’t need to replace the bag filter as often. If the pressure drop reaches a predetermined limit, it is time to change the bag filter. Regular inspection of the bag filter will save energy, cost, and resources.

Q: How Do You Install and Maintain the Bag Filter System?

A: Filter bag housing and filter bags should be installed according to the manufacturer’s instructions and guidelines. The bag filter should not be over-tightened or under-tightened, which can prevent proper sealing and cause leakages. Additionally, technicians must ensure the inlet and outlet valves are opened and closed correctly to sustain proper flow. Finally, the bag filter requires regular inspection and maintenance to prevent product contamination, early wear, and other problems.

Q: What Is the Difference Between a Single Bag and a Multi-Bag Filter Housing?

A: A single-bag filter is ideal for low flow rates and applications with low particle loads. A single-bag filter housing is simpler and costs less than a multi-bag filter housing. A multi-bag filter housing, on the other hand, is suited for high flow rates and applications with high particle loads. Multi-bag filter housings have multiple filter bags, which helps to reduce downtime as one bag can be changed while the other bags continue to filter.

Q: How Can You Extend the Life of Your Bag Filter?

A: The life of a bag filter can be extended by keeping the operating conditions within the recommended operating parameters, having a pre-filtration system in place, and changing the bag filter regularly.

[/bs_col][/bs_row]

Q: Can Bag Filters Be Used for Hazardous Liquids?

A: Yes, bag filters can be used for hazardous liquids. However, the bag material and filter housing must be appropriate for the liquid and the application. For hazardous liquids, bag filters must conform to industry standards and regulatory guidelines.

Bag filters are essential components of industrial filtration systems that are used to remove solid particles and contaminants from liquids to maintain safety and quality. There are different types of bag filters available, each designed for specific applications and operating conditions. Choosing the right bag filter for your application and maintaining it regularly can help to prolong the life of the filter, improve product quality, conserve resources, and reduce downtime. By keeping to their application guidelines and complying with industry standards, bag filters can provide a cost-effective solution for liquid filtration across multiple industries.

Filter Sciences is committed to providing high-quality, commercial-grade filter bag housing products, including bag filters, to meet the diverse needs of our clients. We offer expert advice and technical support on filter selection, installation, and maintenance. If you have any additional questions regarding bag filters or any other filtration needs, please don’t hesitate to contact us. Our team of experienced professionals is always ready to help!