Bag Filtration Housings in the Food and Beverage Industry

Stainless Steel at Carbon Steel Pricing

In Stock | Next Business Day Shipping

Promoting the Health and Safety of Consumers

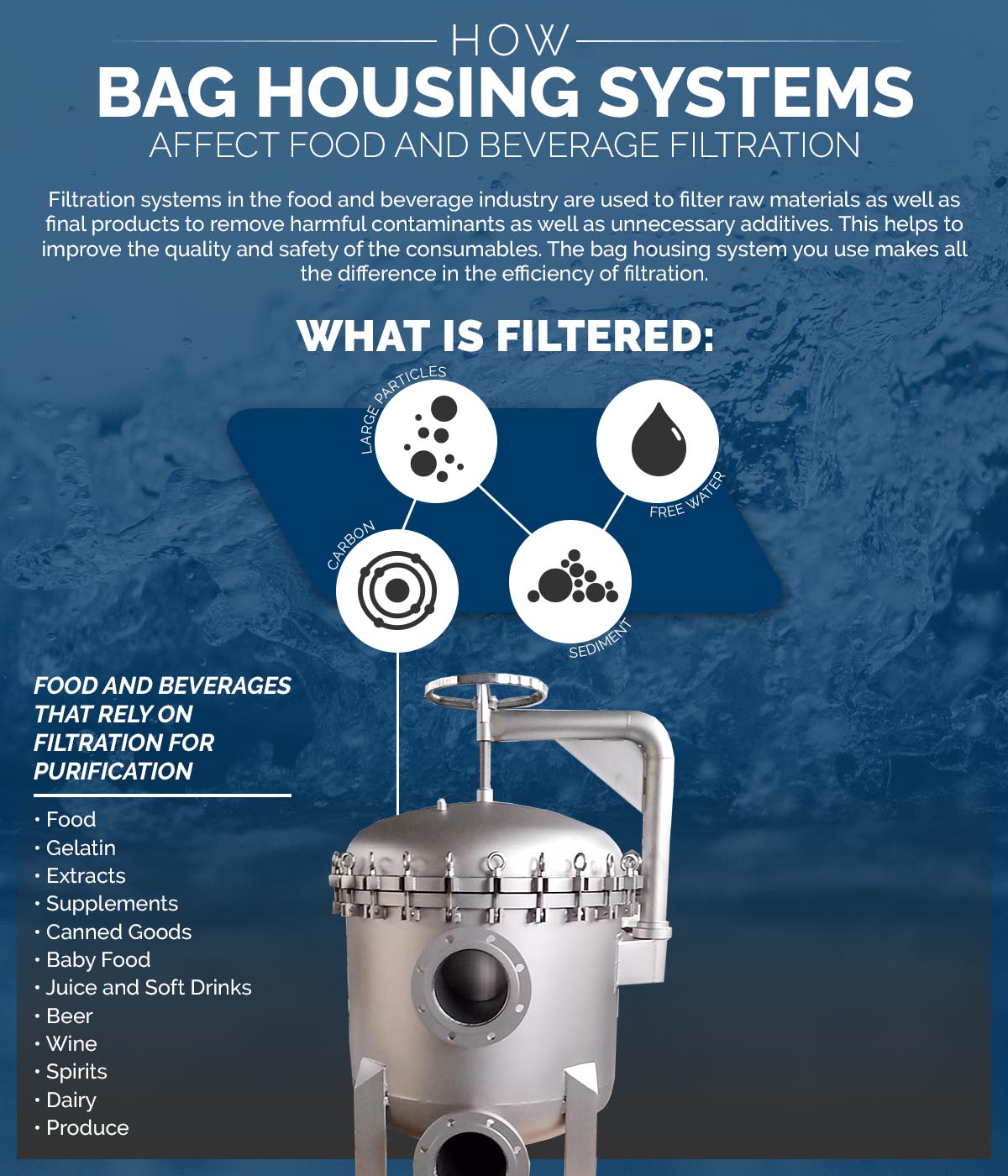

Filtration in the food and beverage processing and manufacturing is a critical component to the health and safety of consumers. Filtration not only helps to improve the consumer’s experience by improving taste, odor, and consistency, but it removes harmful contaminants that help to improve shelf life and prevent illness. Effective filtration depends largely on the bags and bag housing units that are used in the filtration process.

Filtration methods in the food and beverage industry are also used to separate ingredients as part of mass production practices, most notably, in cheese production. While this use has little to do with promoting safety and is more for the creation and end-user satisfaction, hygiene and effective filtration are paramount. Effective filtration improves shelf life and aids in the creation of mass quantities of food and beverage, quicker and more efficiently.

Potable water is one of the most crucial products made by the food and beverage industry that has global effects. Ensuring that drinking water is properly filtered and treated is critical to supporting global health. High-quality bags and bag housing units help ensure the removal of particles, contaminants, microbes, and impurities that create safe drinking water.

At Filter Sciences, we use superior engineering and the highest-quality materials to construct bag housing systems that support hygienic production standards. Bag housing units that are made out of stainless steel offer a sanitary surface that is easy to clean and food friendly. Additionally, stainless steel prevents rusting and corrosion and inhibits microbial growth on the surface. This helps to reduce and contaminant exposure.

The sealed lid-closure system on all of our bag housing units prevents contaminants from entering the bag housing system, as well as prevents fluid and product loss. Filter Sciences offers single or multiple bag housing units with controllable flow rates, which positively contributes to the production of food and beverage products. At Filter Sciences, our bag housing units are assembled in the United States and are ready to ship. Contact us for your quote today.

Recent Posts

Bag Filtration in Oil Production; Upstream, Midstream & Downstream

Bag filtration plays a crucial role in oil production across the upstream, midstream, and downstream sectors by ensuring the cleanliness of fluids and protecting equipment. Here’s how they are used in each stage: 1. Upstream (Exploration and Production): 2. Midstream (Transportation and Storage): 3. Downstream (Refining and Processing): In summary, bag filters are essential for…

Pre-commissioning Piping

Pre-commissioning of piping refers to the series of activities and procedures undertaken before a piping system is put into operation. These activities are crucial to ensure that the piping system is installed correctly, functions properly, and is safe for operation. Bag filtration is the preferred method to remove particulate, debris, dirt, rust, mill scale and…

FSI Ramping Up Production to Meet Demand

At Filter Sciences our production continues to ramp up to meet demand. Strong demand for both 304 & 316 Stainless Bag Housings (filter pots, filter vessels, filter pods) continues to grow in multiple industries. Our commitment to have inventory on hand is and always will be a priority at FSI. Most all our Bag Housings…