Bag Filter Housings for the Automotive Industry

Stainless Steel at Carbon Steel Pricing

In Stock | Next Business Day Shipping

We Focus On One Thing, And One Thing Only, Bag Filter Housings

Superior Bag Filtration Housing Systems — For When Quality and Safety Matter

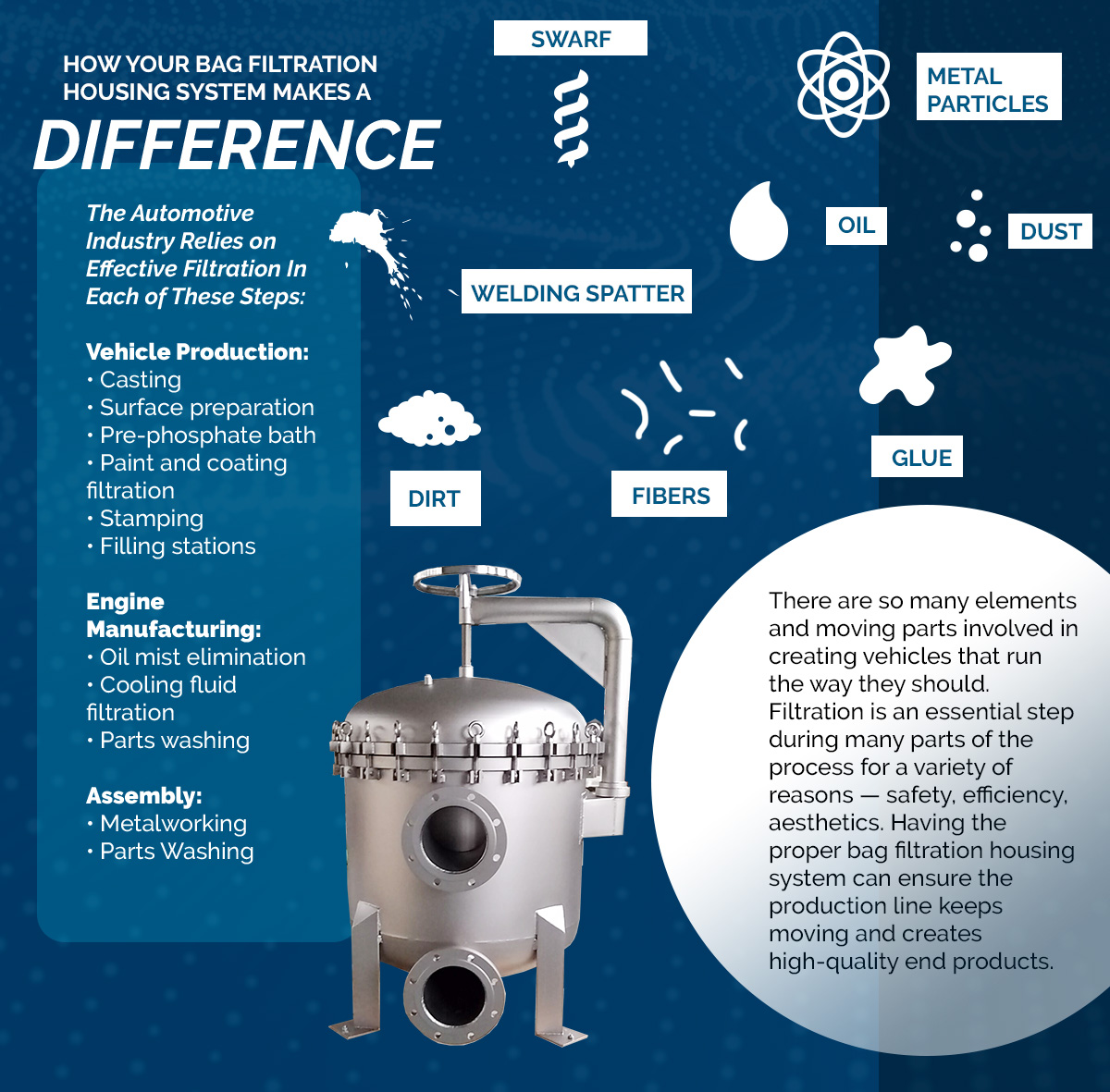

The automotive industry is comprised of many various manufacturing and production plants from individual component creation to assembly and operation of the vehicles themselves. At Filter Sciences, our bag filtration housing systems are used in a variety of automotive applications including:

- Metalworking

- Parts washing

- Casting

- Surface preparation

- Pre-phosphate bath

- Paint and coating filtration

Engineered to Enhance Safety

Proper filtration at every step of the manufacturing, production, and assembly process in the automotive industry is critical to the safety of production workers as well as the end users of the vehicles being made. Faulty bag filtration housing systems that allow impurities to make it through the process can cause unnecessary wear and tear on production machinery and vehicle parts. When you invest in the best-made bag filtration housing units, you can rest assured that your manufacturing, production, and assembly employees are safe as well as the mechanics and drivers of the vehicles you make.

Engineered to Promote Productivity

The automotive industry is dependent on the performance of the machinery that drives production. When process fluids are not filtered properly, it allows contaminants such as dust, metal particles, and oil to clog up the moving parts of machines and causes undue wear and tear, quickly putting your production line on a stall. When you effectively remove all of the particles and debris from the process, you ensure that your machinery keeps working and your production line keeps moving.

Engineered for Superior Quality

A single fiber that makes it through the bag filtration housing system will result in less than perfect sealants, paint, or coating that may result in costly re-work, or, if missed, may result in preventable corrosion. When dust, bacteria, welding spatter, or glue makes it through the filtration process in the manufacturing of parts, it can lead to delamination of paint, poor parts fitting, or rough surfaces that must be corrected or remade. When quality matters, be sure you have a bag filtration system you can count on.

At Filter Sciences, we use superior engineering processes and materials to create bag filtration housing units that meet your needs and exceed standards. This allows you to keep production moving and create high-quality end products that are safe and reliable. For your custom quote, connect with us today.

Recent Posts

Bag Filtration in Oil Production; Upstream, Midstream & Downstream

Bag filtration plays a crucial role in oil production across the upstream, midstream, and downstream sectors by ensuring the cleanliness of fluids and protecting equipment. Here’s how they are used in each stage: 1. Upstream (Exploration and Production): 2. Midstream (Transportation and Storage): 3. Downstream (Refining and Processing): In summary, bag filters are essential for…

Pre-commissioning Piping

Pre-commissioning of piping refers to the series of activities and procedures undertaken before a piping system is put into operation. These activities are crucial to ensure that the piping system is installed correctly, functions properly, and is safe for operation. Bag filtration is the preferred method to remove particulate, debris, dirt, rust, mill scale and…

FSI Ramping Up Production to Meet Demand

At Filter Sciences our production continues to ramp up to meet demand. Strong demand for both 304 & 316 Stainless Bag Housings (filter pots, filter vessels, filter pods) continues to grow in multiple industries. Our commitment to have inventory on hand is and always will be a priority at FSI. Most all our Bag Housings…