Natural gas is the fossil fuel we all use that is a source of energy that make our daily lives more comfortable and time-efficient. From driving our cars and cooking meals, to heating our homes and providing electricity, it would be hard to go a day without it. Natural gas is formed from millions of years of plant and animal decomposition combined with the perfect conditions of intense heat and pressure beneath the Earth’s surface. The energy from the plant and animal material is stored in the Earth’s interior chemically bonded as gas.

To access this non-renewable resource, technologies have been developed to penetrate the deep underground coal beds and methane clathrates to access these hydrocarbon reservoirs.

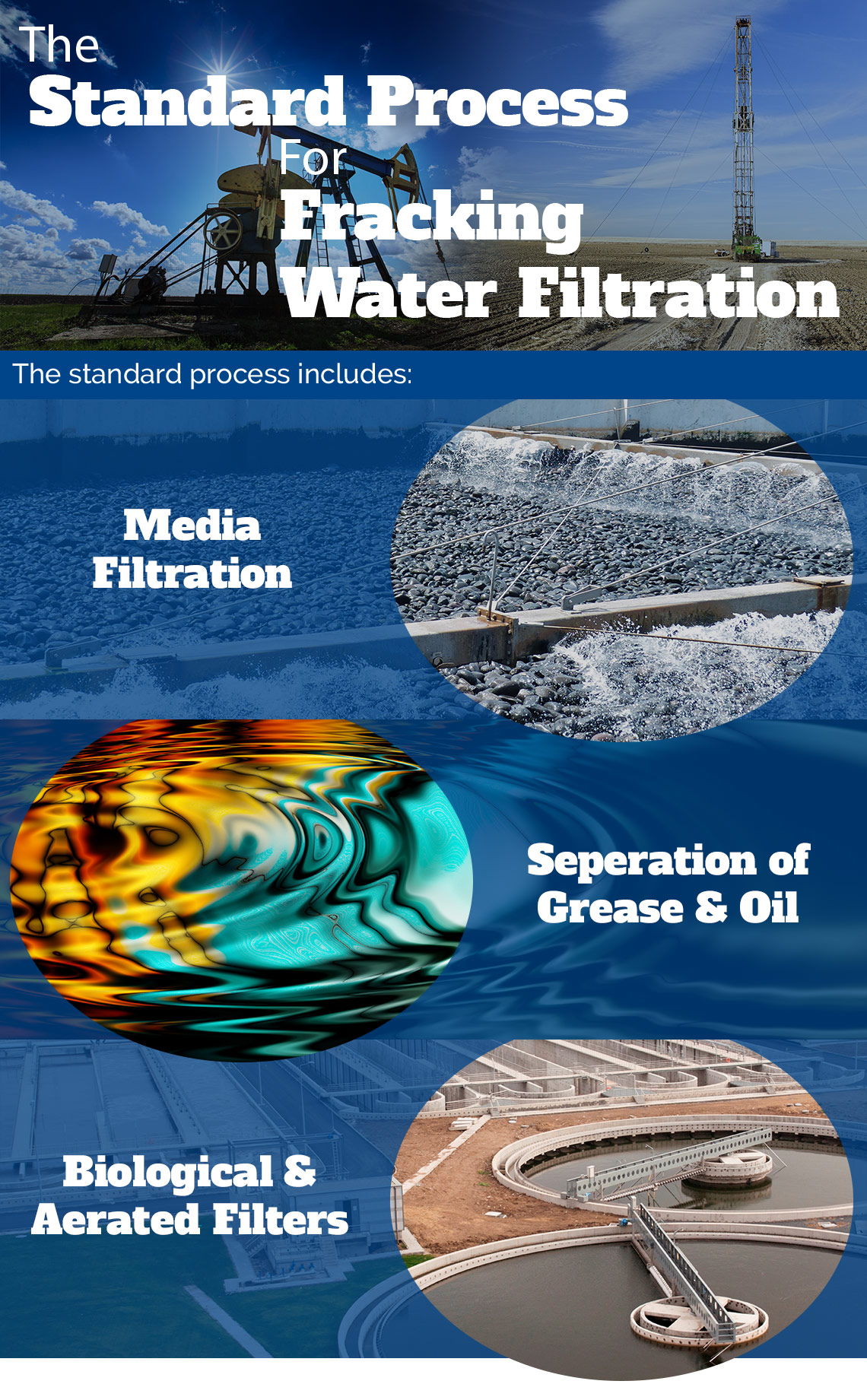

Hydraulic fracturing (fracking) is the manner in which we extract natural gas. In this process, water needs to be filtered, which is where Filter Sciences assists the industry. Our filter bag housings and filter media play a crucial role in this. To learn more about how hydraulic fracturing implements our filtration products, follow along in today’s post.

How Fracking Works

As we mentioned above, fracking is used to extract natural oil and gas within the shale rock formation. It is done by pumping sand, chemicals, and water at high pressures, into the injection site. The steps of obtaining natural gas will vary from company to company, as they all have a proprietary process in the way they use chemicals, so there is very little public information on it.

As we mentioned above, fracking is used to extract natural oil and gas within the shale rock formation. It is done by pumping sand, chemicals, and water at high pressures, into the injection site. The steps of obtaining natural gas will vary from company to company, as they all have a proprietary process in the way they use chemicals, so there is very little public information on it.

As chemicals, sand, and water are injected, because the pressure is so high, some of the fluids flow back to the surface ground, and this is known as “flow back” water. “Flow back” water can become a salty and briny solution which will increase the rate of corrosion on a carbon steel filter housing. This is why many contractors and companies within the oil and gas industry choose stainless steel filter housings from Filter Sciences to prolong the life of their filter bag housing and increase ROI.

Over time, the amount of flow back decreases while the water flow increases. On average, three to five million gallons of water is used, and of this, one-third of it is flow back.

How Frack Water is Treated

One manner in which frack water is disposed of is in deep wells, which are drained oil and gas sites. The water is generally filtered depending on the types of solids that are present. If there is no access to deep wells, the frack water will be reused and blended with fresh water at another well. The frack water that is reused has to meet specific requirements and with quality filter media and filter bag housings, they keep the following to a minimum:

- Total suspended solids (TSS)

- Total dissolved solids (TDS)

- Metals

- Hardness

The dilution of fresh water to a 20:1 ratio of reused frack water. If fresh water is unavailable or there are not as many sites being drilled, the water is treated to meet the companies’ conditions.

Filter Sciences and Fracking

Our filter media and filter bag housings are implemented in fracking when there are high concentrations of TDS in the brine and the disposal is above ground, or when treatment facilities are unable to remove the salts (which most are unable to do).

Many times our filters are mounted on a skid loader for easy loading on a truck or trailer for mobile transport. Being able to filter frack water on site with media filtration allows companies to save money while meeting filtration specifications.