Filter Bag Housing in the Metal Working Industry

Stainless Steel at Carbon Steel Pricing

In Stock | Next Business Day Shipping

Keeping Production at an All-Time High

Metalworking Fluid Filtration

Metalworking is a collective term that encapsulates several processes, each serving its own purpose to meet the demands of productivity and manufacturing. Machines are the driving force behind the metalworking industry and are used to provide rapid results. If there is a breakdown in the system, productivity is halted, costing time and efficiency.

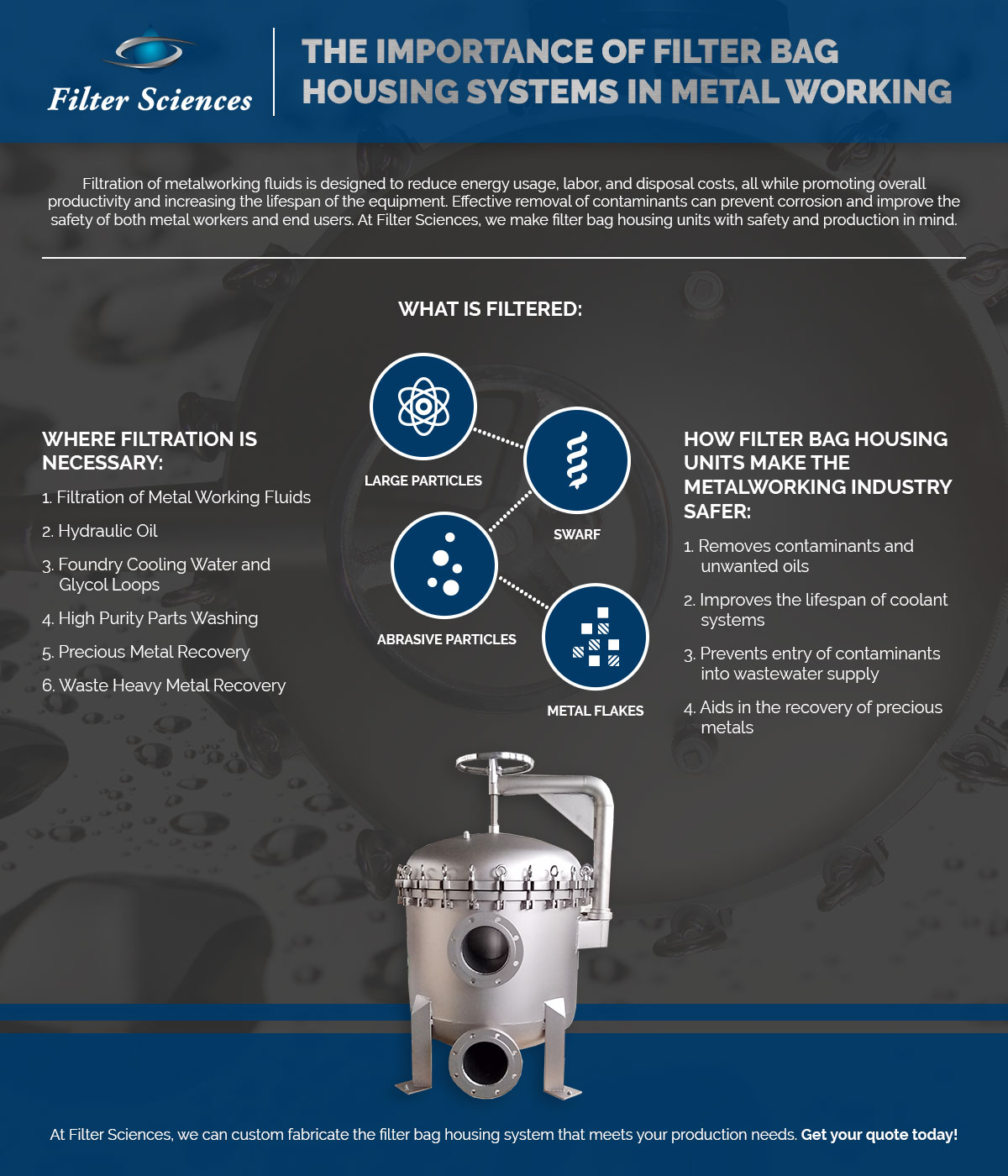

Metalworking fluids are those that facilitate the operation by reducing wear on machinery, keeping machinery cool, and washing parts, tools, and washing away impurities. To safely remove contaminants and oil from metalworking fluids for reuse or disposal, proper filtration is a critical part of safety and efficiency.

Filter bag housing units provide the framework for the filtration process and aid in contaminant removal. For metalworking fluids, hydraulic oil, foundry cooling water and glycol loops, high-purity washing parts, precious metal and waste heavy metal recovery, filter bag housing systems from Filter Sciences are what will help keep your systems operating.

Founded on Quality and Integrity, Backed by Science and Superior Engineering

When it comes to metalworking, there is no room for shortcuts that may compromise safety, productivity, and the quality of end products. At Filter Sciences, we use superior engineering practices to create filter bag housing units that support the machinery that fuels the metalworking industry. Our stainless steel filter bag housing units are available at carbon steel pricing and are assembled in the United States. Because we engineer and create all of our filter bag housing systems, if we do not have what you need in stock, we can custom engineer one to meet your specific regulatory and operational requirements. Contact us for your custom metalworking filtration quote today.

Recent Posts

What is the unit of measurement called a MICRON?

A micron, also known as a micrometer, is a unit of measurement equal to one millionth of a meter. To put this into perspective, a human hair is typically around 50 to 100 microns in diameter. This means that a micron is incredibly small, making it useful for measuring very fine particles or features. In…

Enhancing Cooling Tower Efficiency with Bag Filtration for Industrial Water

Cooling towers are essential components in various industrial processes, from power generation to manufacturing. They help regulate temperature by removing heat from systems, ensuring optimal performance and preventing overheating. However, the efficiency and longevity of cooling towers can be compromised by contaminants such as dirt, debris, and biological growth. This is where industrial water filtration…

EPA Requirements for Water Filtration in Fracking and the Vital Role of Bag Filtration

EPA Requirements The Environmental Protection Agency (EPA) has established various guidelines and regulations to mitigate the environmental impacts of hydraulic fracturing, commonly known as fracking, particularly focusing on water quality and safety. The key EPA regulations related to water management in fracking include: Water Acquisition: This involves the withdrawal of large volumes of groundwater or…