Bag Filtration Housings for the Oil & Gas Industry

Stainless Steel at Carbon Steel Pricing

In Stock | Next Business Day Shipping

We Focus On One Thing, And One Thing Only, BAG FILTER HOUSINGS

Where Our Liquid Bag Filter Housings Are Used in the Oil & Gas Industry:

- Hydraulic Fracturing

- Salt Water Disposal Wells

- Wastewater

- Power generation

- Oil Bypass

- Environmental Remediation

- Cooling Tower Water

- Recycling Frac Water

Salt Water Disposal Wells - Superior Bag Filtration Housing Systems

In the oil and gas industry, the responsible management of produced water is a top priority. As a byproduct of extraction processes, produced water contains contaminants that must be effectively treated before disposal. Bag filtration has emerged as a vital technology in this realm, particularly in the context of saltwater disposal wells. This article explores the significance of bag filtration, its role in treating produced water, and the benefits it brings to saltwater disposal operations.

Produced Water Challenges:

Produced water from oil and gas extraction processes often contains a complex mixture of contaminants, including suspended solids, hydrocarbons, and various chemicals. Efficiently addressing these challenges is essential to safeguard the environment and comply with regulatory standards. Saltwater disposal wells, designed to inject produced water into deep geological formations, rely on advanced filtration technologies to ensure the injected water meets stringent quality requirements.

Bag Filtration Overview:

Bag filtration is a mechanical separation process that involves passing produced water through a series of porous filter bags. These bags, made of materials like polypropylene or nylon, capture suspended solids and other particulate matter, allowing for the production of clarified water suitable for injection into disposal wells.

Key Components and Operation:

- Filter Housing:

- Bag filtration systems consist of a filter housing, which holds the filter bags in place. The housing is designed to withstand the high pressures and flow rates associated with produced water treatment.

- Filter Bags:

- Filter bags are the heart of the bag filtration system. These bags come in various sizes and materials, each tailored to the specific needs of the produced water being treated. They effectively trap particles, preventing them from reaching the disposal well.

- Multi-Stage Filtration:

- FSI Bag filtration systems often incorporate multiple stages with progressively finer filter bags. This multi-stage approach enhances the filtration efficiency and ensures the removal of particles of varying sizes.

Benefits of Bag Filtration in Saltwater Disposal Wells:

- Particle Removal:

- FSI Bag filtration is highly effective in removing suspended solids, sediments, and other particulate matter from produced water. This is crucial in preventing well clogging and maintaining the integrity of the injection zone.

- Extended Well Life:

- By preventing the injection of abrasive particles, bag filtration helps extend the life of saltwater disposal wells. Reduced wear and tear on well components contribute to prolonged operational efficiency.

- Compliance and Environmental Protection:

- Bag filtration ensures that the quality of injected water meets regulatory standards. This not only protects the integrity of underground water sources but also safeguards surface water and soil from potential contamination.

- Cost-Efficiency:

- The use of bag filtration systems can lead to cost savings by minimizing maintenance requirements and optimizing the performance of saltwater disposal wells.

Conclusion:

Bag filtration plays a crucial role in enhancing the treatment of produced water for saltwater disposal wells. As the oil and gas industry continues to prioritize environmental sustainability and regulatory compliance, the adoption of advanced filtration technologies like bag filtration becomes increasingly important. By efficiently removing contaminants, bag filtration contributes to the overall success and longevity of saltwater disposal operations, ensuring that the industry remains responsible stewards of the environment.

Liquid Management in the Oil & Gas Industry

The oil and gas industry, namely hydraulic fracturing and salt water disposal wells, are using industrial filtration more than ever to filter liquids in various stages of the process.

While fracking is a hot topic, it is an industry that has been around for more than half a century, and though it uses an exorbitant amount of water, throughout the decades, new and innovative protocols have been developed to better conserve water.

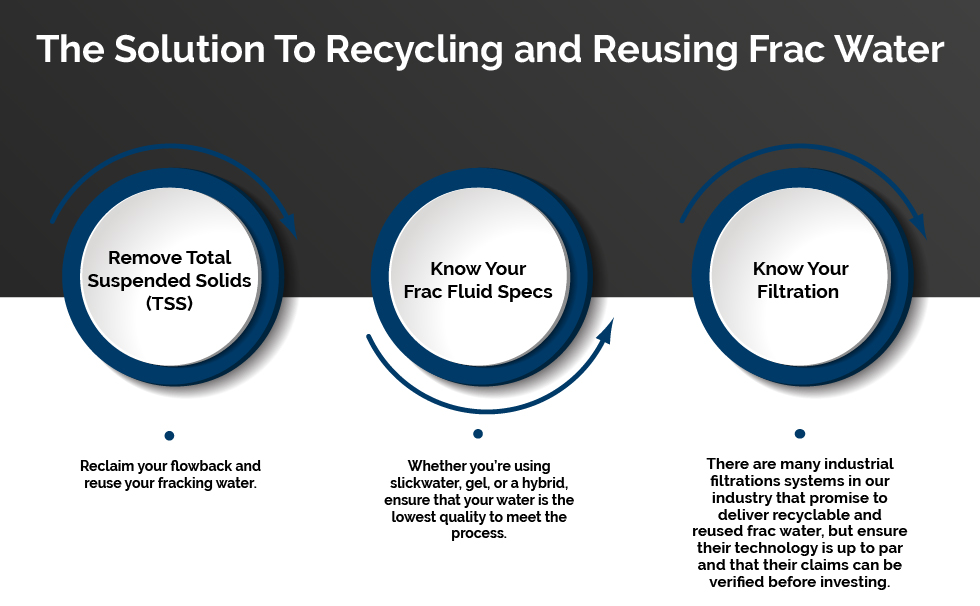

Filter Sciences supports the fracking industry by providing them the technology to better filter and reuse water to aid in the conservation efforts. Join us in today’s post as we take a deeper look into industrial filtration and frac water management.

From Upstream and Midstream, All The Way to Downstream Applications

There are various stages that fracking uses water, let’s dive into each of them below.

Upstream Wastewater: Saltwater Disposal

Fracking requires the disposal of salt water or produced water and along with it, the removal of grit and sand.

Upstream, Midstream, and Downstream: Filtration

This stage requires filtration and integration for the elimination of solids, water, and oil.

Upstream: Fracturing Water

Fracking water is produced from water that needs to be further filtrated to remove other solids and particulates that may hinder the fracking process — filter bags employed typically go down to 10 microns.

The Frac Sand

When companies begin drilling, water and sand are infused to the ground at a very high rate to essentially crack open the shale, where the natural gas and oil are housed. The sand is also known as “proppant.”

The fracking sand is much different than the sand you find on a nice sunny beach, in that it needs to be cleaned, screened, and washed. Because the demand for sand is so high, it’s a continual process to create clean and uniform sand to be used in breaking the shale.

What is there to wash from the sand?

The sand is rinsed clean of any minerals and clays before it’s pumped into the drill site — from here, the water is further processed through a filter press at a high flow rate.

The Frac Flowback Water

As the water and sand are pumped into the ground at a high rate, the drilling hole eventually fills with water and sand. When this is complete, the drill exits, and the water and sand and forced through pressure to return to the surface. One way to imagine this is by filling a balloon with water. As the balloon expands and fills through water pressure it stays put, but once it’s removed, the water comes spraying back out! This is essentially the fracking flow backwater. Beyond what comes back to the surface, there is also water underground known as produced water.

The water that surfaces through the fracking process may contain sodium, heavy metals, magnesium, barium, calcium, radioactive materials, and hydrocarbons — this must all be filtered and purified before it can be reused. A typical frack job uses anywhere from three to five gallons and roughly one-third of that will return to the surface.

How water is both filtered and treated is important to the fracking industry because not only is it important to conserve and reuse water for ecological sustainability, it’s vital to keep the water safe, and particulate-free.

Fracking & Salt Water Disposal Well Filtration With Filter Sciences

At Filter Sciences, we provide an innovative, stainless steel filter bag housings that complement many filter media, making them work with the intricacies of the hydraulic fracturing industry.

Not only can we assist in the standard process of total suspended solids, particulate, and inorganic material, we can help guide your operation towards optimal efficiency for filtration equipment that does exactly what you need.

Partner with us today and discover why our industrial filtration is right for your industry!

Recent Posts

When to Replace a Filter Bag?

Welcome to Filter Sciences, the industry leader in providing unparalleled filtration solutions for a wide range of industries. Our commitment to excellence and innovation has positioned us as the go-to choice for businesses seeking superior filtration performance. In this blog, we invite you to explore the remarkable features and benefits of Filter Sciences’ filter bags.…

What Do Bag Filters Move?

Bag filters are an essential part of many industrial processes, providing effective filtration for a wide range of materials. But what exactly can bag filters move? In this guide, we’ll explore the capabilities of bag filters, how they work, and the benefits they offer. Filter Sciences is a leading provider of bag filters and…

What Is The Purpose Of A Bag Filter?

If you work in or own a large factory, oil & gas plant, chemical processing plant, or any other industry that deals with liquids, you know the importance of having a reliable filtration system in place. Filters not only keep water supplies safe, but they also refine and clarify production liquids like cooking oil and…