Bag Filter Housing in the Pharmaceutical Industry

Stainless Steel at Carbon Steel Pricing

In Stock | Next Business Day Shipping

Allowing For the Creation of Sterile Products

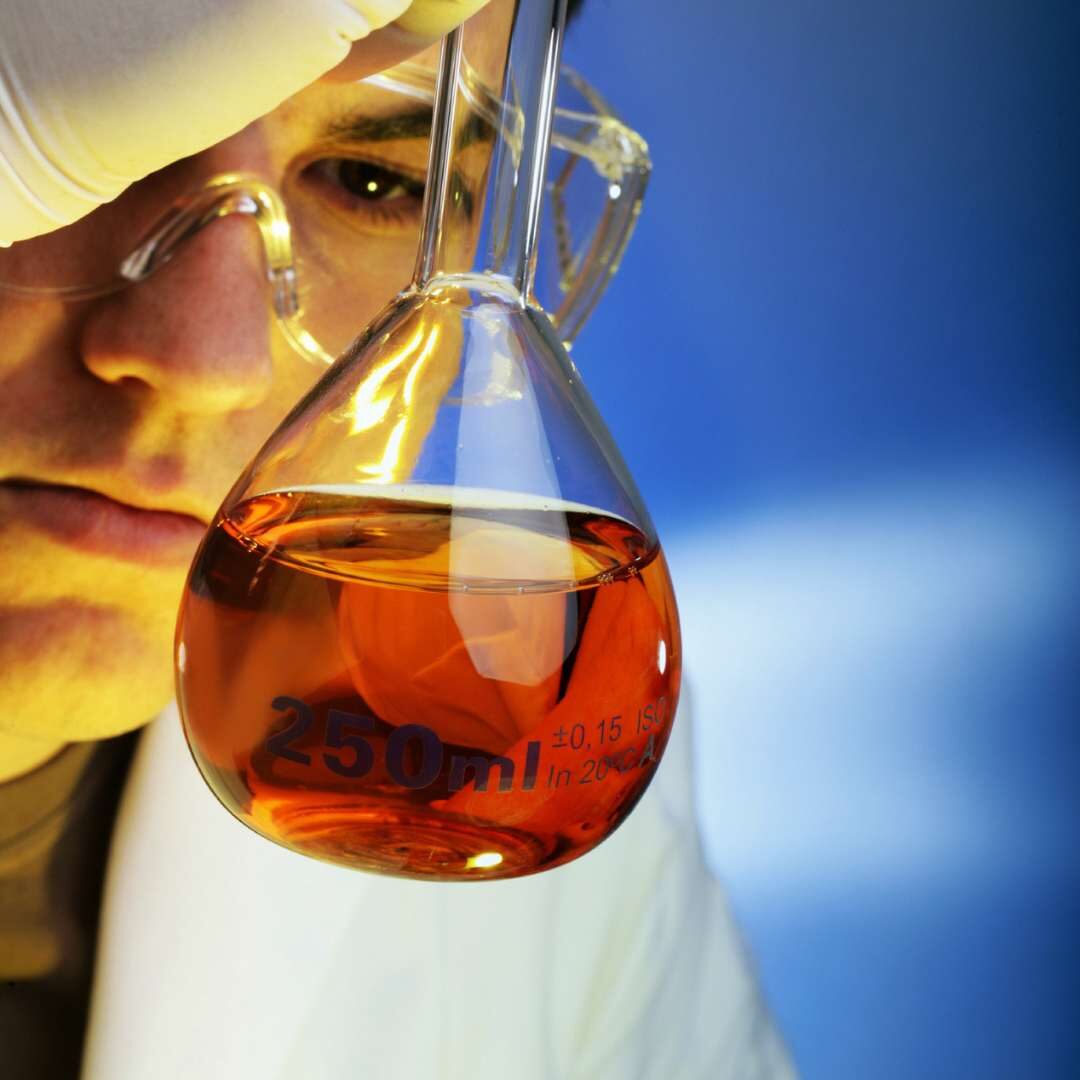

Pharmaceuticals– Filtration is a critical step in the creation of sterile pharmaceutical products including bulk drugs and liquid oral suspensions. In the production of biopharmaceuticals, a five-step filtration process is employed to produce sterile medications that are as chemically pure as possible. To make the process reliable, all of the components in the chain of manufacturing must positively contribute. When a stainless steel bag filter housing system is used, it prevents leaking and corrosion and provides a seal that maintains the sterile integrity of the product within.

Nutraceutical– Because nutraceutical manufacturing falls in the grey area between consumables, that are regulated by the Food and Drug Administration, and pharmaceuticals, they are subject to a combination of strict requirements and regulations. Quality control procedures, ingredient testing, and safety are paramount. Choosing the right bag filter housing can help ensure that the nutraceuticals that are produced are as pure as they can be.

If your products will be worn or consumed by the public, it is your duty to ensure the entire process maintains the highest integrity standards. Bag filter housing from Filter Sciences offers assurance and reliability that helps you create safe, sterile products you can be proud to offer the public. Our bag filter housing systems are assembled in the United States and are in stock, ready to ship. Contact us for your free quote today.

Recent Posts

Tesla, Improves Quality with Filter Sciences

“Filter Sciences Manufacturers Custom Solution for Tesla”. Tesla looked to improve the quality in their Pre-treat and E-coat processes prior to paint. Filter Sciences designed and manufactured a custom bag filter housing solution. Removing particulate down to the micron level improved adhesion and overall paint quality. Our full- service solutions and field expertise helped identify…

Salt Water Disposal Well Filtration

“For every barrel of oil produced an average of 3 to 5 barrels of water is consumed”. A salt water disposal well is a disposal site for water produced as a result of the oil and gas extraction process. Produced water, also referred to as salt water, contains particulate which can cause problems for the…

Bag Filters over Cartridge Filters

1. COST – The cost of replacing the filter media is one aspect; others include frequency of replacement and waste disposal cost. The frequency of replacement addresses not only the annual units of media to be purchased but also the number of interactions personnel have accessing the vessel and exposing themselves to the fluid, so…