Industries Using Filter Bag Housings

We Focus On One Thing, & One Thing Only, Bag Filter Housings

When the USS Monterey needed a filtration system delivered in under 24 hours over the July 4th weekend they called Filter Sciences.

When fracking companies begin drilling, water and sand are infused to the ground at a very high rate to essentially crack open the shale, where the natural gas and oil are found. The sand is rinsed clean of excess minerals and clay before it is pumped into the drill site. Then the water is processed through a filter press at a high flow rate.

Effective bag filtration helps to remove suspended solids. At Filter Sciences, we provide stainless steel filter bag housings that accommodate many filter media specified for use in the hydraulic fracturing industry and salt water disposal wells.

At Filter Sciences, we can assist you in the removal of total suspended solids, and particulate, we can help guide your operation towards optimal efficiency by providing bag filtration equipment that does exactly what your fracking service or salt water disposal well company requires.

In many applications of water treatment and management, effective filtration of particulates is a critical component of the quality of end products as well as the functioning of machinery down the line. Bag filtration is useful in removing sand, silt, algae, particulates, calcium deposits, and other matter from wells, cooling towers, and agricultural irrigation, among other uses.

Cooling Tower Water Filtration

In HVAC systems, cooling water is collected in cooling towers to be filtered prior to being reused to protect the components of the HVAC system — heat exchangers, chiller tubes, evaporative condensers, cooling tower basin, piping system — from scale, corrosion, fouling, and biological activity. This helps ensure long-lasting equipment and better quality downflow. Effective bag filtration can remove large particulates and efficiently remove them before the water is reused.

Well-Water Filtration

Well water, while fresh, is often of poor quality and requires additional filtration before it can be used for any purpose. Filter bag housing units allow well water to undergo the first phase of water filtration and can remove solids including vegetation, sand, silt, insects, and algae, among other contaminants. This helps reduce clogs in subsequent filtration steps and keeps water cleaner.

At Filter Sciences, we produce high-quality stainless steel bag filter housing units that can hold up to the moisture without the worry of corrosion, offers sure-seal closures, and can withstand nearly any flow rate! Discover more about how we can help with your water filtration needs and contact us to place your stainless steel bag filter housing order today

When fracking and or salt water disposal well companies begin drilling, water and sand are infused to the ground at a very high rate to essentially crack open the shale, where the natural gas and oil are found. The sand is rinsed clean of excess minerals and clay before it is pumped into the drill site. Then the water is processed through a filter press at a high flow rate.

Effective bag filtration helps to remove total suspended solids. At Filter Sciences, we provide stainless steel filter bag housings that accommodate many filter media specified for use in the hydraulic fracturing industry and in salt water disposal wells.

At Filter Sciences, we can assist you in the removal of total suspended solids, particulate, and inorganic material, and we can help guide your operation towards optimal efficiency by providing bag filtration equipment that does exactly what your fracking service or salt water disposal well company needs.

The food and beverage industry relies heavily on effective processing. Bag filtration helps to improve both the safety and the quality of food and beverage products. From the production standpoint, effective filtration can help protect machinery down the line as well as reduce waste, in essence, protecting your bottom line.

At Filter Sciences, our stainless steel bag filter housing units are made to withstand various temperature limits and corrosion while providing a sure seal and easy sanitation. Because our housing bag filters are made of stainless steel, they will not corrode the way carbon steel does, helping to ensure your product line runs smoothly. We provide the filtration that food and beverage companies rely on for consistency and quality. Contact us for your custom quote today.

Water in the metalworking industry is incredibly important to function as a protective coolant and lubricant as well as rinse and clean during the process. Metalworking fluids of all types, including water, other lubricants, and by-products pose a particular risk for affecting the safety of metalworkers and the lifespan of the equipment. Bag filter housing systems help to filter metalworking fluids to remove large impurities including swarf, metal flakes, and abrasive particles to prevent them from reentering the process down the line. This aids in increasing the lifespan of the equipment by reducing energy usage and labor costs. Effective filtration allows for the reuse of metalworking fluids with saves in disposal costs.

At Filter Sciences, we understand the filtration needs of the metalworking industry and have the housing filtration units you can count on. Our stainless steel filtration systems can be used with hydraulic oil, foundry cooling water, and glycol loops, precious metal recovery, and high purity parts washing. Visit our metalworking page to learn more and contact us for your custom quote today.

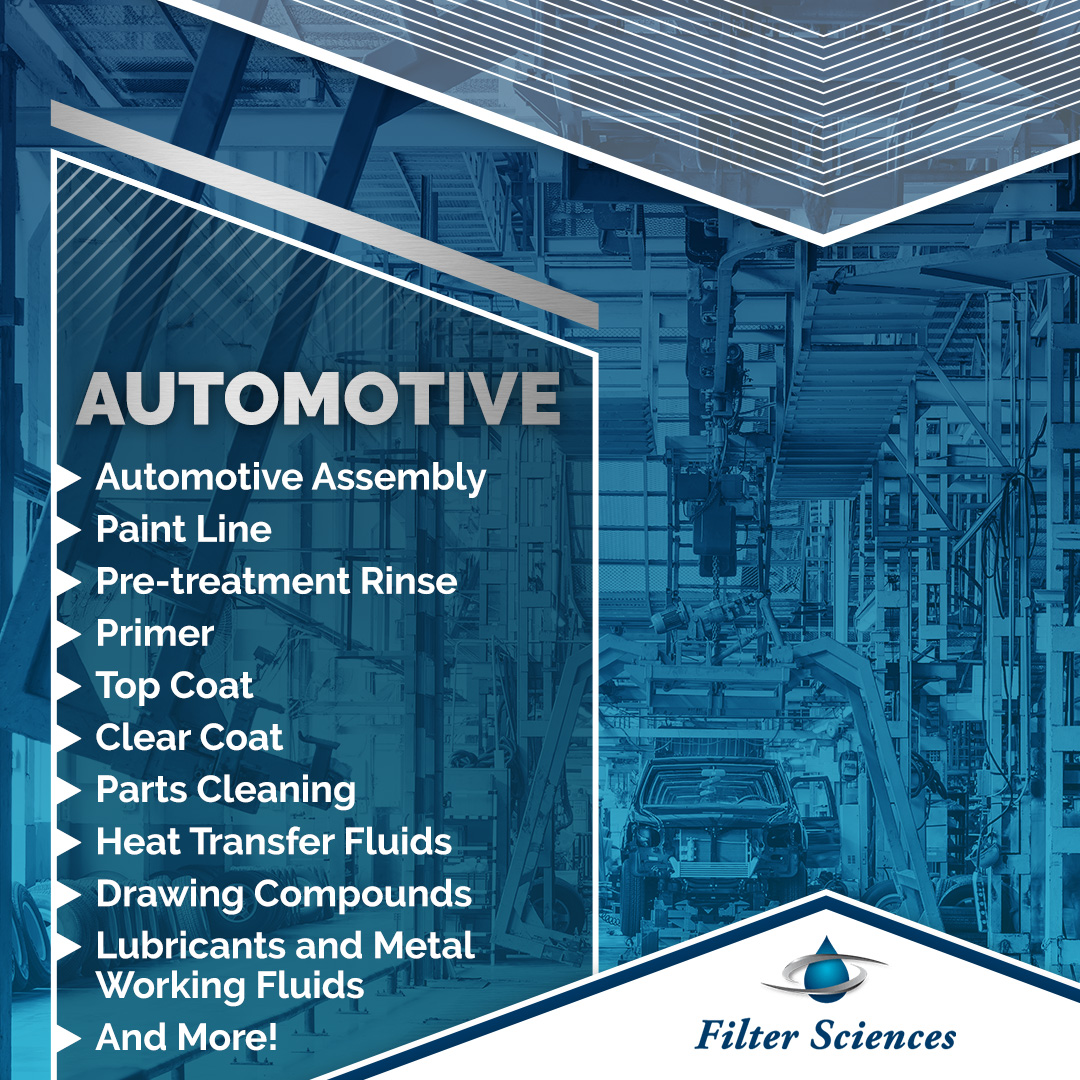

From the backwash from automotive metalworking to the paint and lacquers used to cover vehicles and all the fluids in between, the automotive industry depends on effective filtration techniques and equipment. Every step of the automotive assembly and repair process depends on the fluids that support it. The right bag filtration housing makes all the difference in the outcome and lifespan of the vehicle.

At Filter Sciences, we create bag housing systems that keep the automotive industry running. Our stainless steel engineering prevents corrosion and offers high abrasion resistance. Regardless of what area of the automotive industry your company functions in, we’ve got the equipment to meet your needs. Learn more about our filter housing units and contact us for your custom quote today.

Reliable filter bag housing systems are essential in nearly every application that includes liquid runoff or backwash. This includes the plastic, resin, ink, and coating production industries. Liquid byproducts, as well as rinse fluids, should be filtered to remove large particulates that may damage downline equipment or alter the consistency of the product being made. In many plastic and resin applications, additional fluid is added to reduce dust and keep end products smooth.

At Filter Sciences, we create filter bag housing units that support these industries and keep manufacturing moving. Some ways our filtration systems improve the process include oil and polymer filtration, ingredient dispersions, polymerization batch filtration, plastics compounding, printing ink filtration, and high-purity ink-jet fluid filtration. Contact us for your custom quote today.

The pharmaceutical and nutraceutical industries are reliant on effective filtration to produce safe end products and reduce toxic waste. Bag filtration helps to remove impurities, particles, calcium deposits, proteins, gelatins, and activated carbon during the manufacturing process. Bag filtration is effective for the filtration of oil-based products and liquid pharmaceuticals and assists in polishing herbal mixtures.

At Filter Sciences, our bag filtration housing units are made of stainless steel which is corrosion resistant. Our single and multi-bag housing systems offer high abrasion resistance and can ensure that contaminants and particles are removed without damaging the filter, equipment, or the end product. Filter media allows for high separation and filtration efficiency and is resistant to chemical damage.

Visit our pharmaceuticals page online and contact us for your custom quote.

From small-batch commercial chemical processing to industrial-grade chemical processing, your processing plant relies on a filter bag housing system that can keep up and won’t break down under pressure. The chemical processing industry involved a variety of substances and quantities. From batch to continuous operation, your production line depends on the equipment that keeps it running. In addition to making end products safe, bag filtration is important to protecting your production line workers as well as extending the lifespan of machinery.

At Filter Sciences, we manufacture stainless steel filter bag housing units that are corrosion resistant and sure-seal covers to prevent leakage or contamination. Our filtration units can handle large flow rates and can withstand a wide range of temperatures. For all of your filter bag housing unit needs, contact us for your custom quote. Learn more by visiting our chemical processing page.

The quality of paint and lacquers is largely dependent on the consistency of the product. For this reason, filtration in the paint and lacquer industry has one of the biggest impacts on the quality of the end product. Effective bag housing filtration removed particles and impurities and improves texture and consistency in paint, lacquer, varnish, ink, and coatings.

At Filter Sciences, we understand the importance of filtration in the manufacturing and production of paint and lacquers and create bag filter housing systems that can keep up. Our stainless steel bag housing units are able to remove agglomerates, coagulates, solvents, and films without corrosion. All of our units feature sure-seal closures that prevent the introduction of dust or contaminants in the product. Whether you manufacture small batches or industrial-grade products, we’ve got the right bag housing unit to meet your needs. Learn more on our paint and lacquer page and contact us for your custom quote today.

Recent Posts

What Size Filter Bag Housing Do I Need?

Choosing the correct size filter bag housing is an essential part of ensuring optimal filtration in industrial applications. Filter Sciences specializes in supplying top-of-the-line commercial-grade water filters, including filter bag housings. In this blog post, we will explain the factors that need to be taken into account when determining the ideal size filter bag housing…

Single Bag vs. Multi-Bag Housings: The Differences

When it comes to choosing the right equipment for your industrial needs, finding the best products and the most trustworthy companies to work with can be a top priority. However, getting what you need and ensuring that it’s cost-effective and lasts for years is another important factor. At Filter Sciences, we’re proud to offer top-quality…

Bag Filters FAQs

Here at Filter Sciences, we strive to provide only the highest quality, commercial-grade filtrations systems to remove particles and other contaminants from liquids to maintain safety and quality for our clients. One of the vital components of any industrial filtration system is the filter bag housing and the bag filter itself, which is used to…