Bag Housing in the Food and Beverage Industry

Stainless Steel at Carbon Steel Pricing

In Stock | Next Business Day Shipping

Nothing But Quality Coating

Quality End Products Start With Superior Filtration at the Beginning

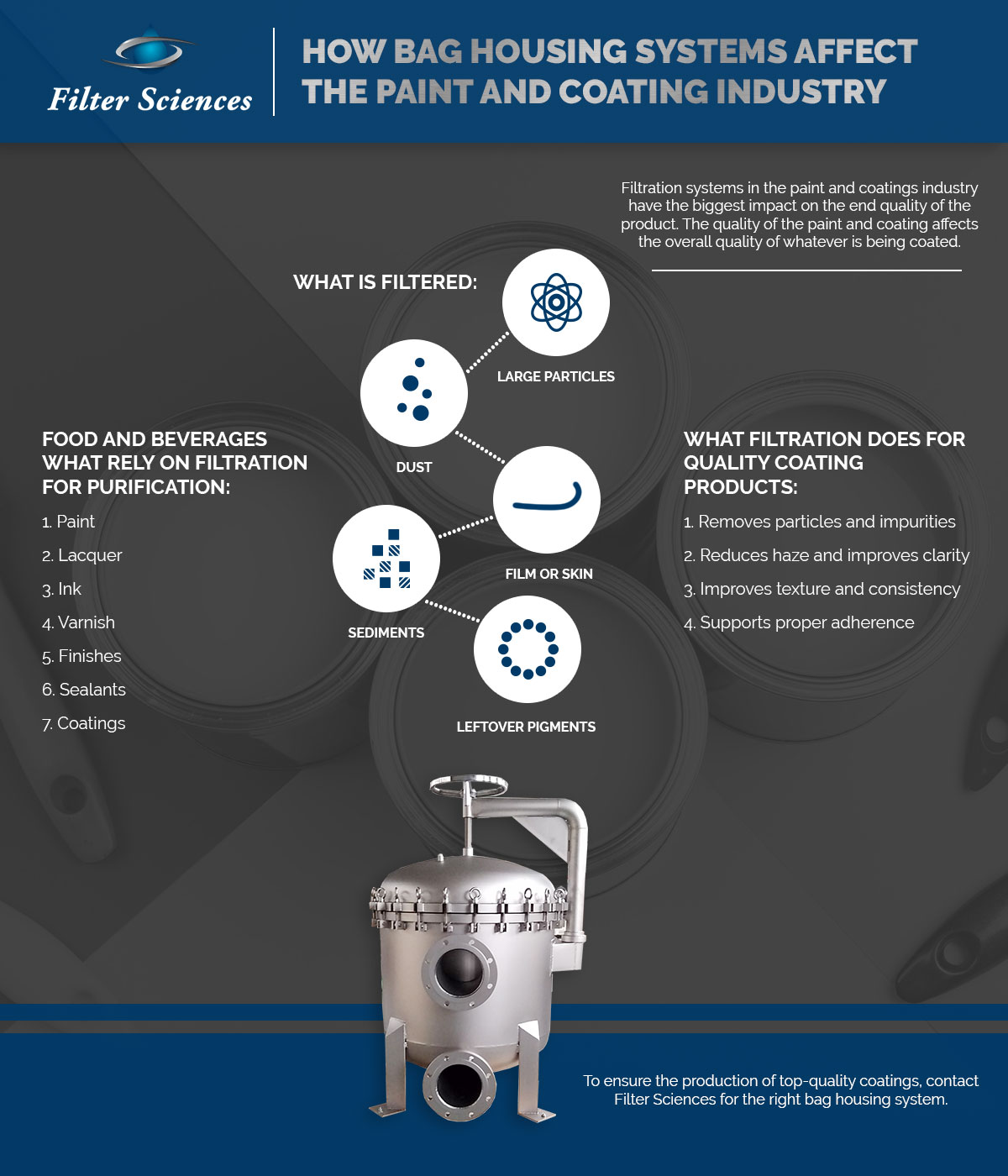

Creating top-quality end products begins with ensuring the best raw materials are used. In the coating and paint industry, assuming that the liquid base materials are properly filtered is not a safe bet. Good filtration practice should begin with the liquid raw materials including resin, emulsions, water, oil, and liquid additives that will be combined to create the end product.

During the coating process, other impurities can be trapped, introduced, or created. For instance, some natural oils and pigments can introduce foots — the small pieces of leftover hull that are created during the grinding process — that can create sediment, ruining entire batches of paint. Some ingredients, when left to sit at different temperatures, can create film or skins that, when mixed with the wet coating beneath, can cause lumps that clog product containers and prevent the use of the coating.

Proper filtration is the solution to quality assurance in any coating product. From the first step to the last, ensure that the materials are properly filtered by using the best-quality bag housing units.

Special Considerations in Paint and Coating Filtrations

Unlike other industries where most, if not all, solids must be removed from the liquid to leave behind a purely filtered product, paints and other finishes have a variety of special considerations where some solids should remain — talc, pigments, aluminum flakes — while most others, even those of similar size and shape should be removed. For this reason, a standard bag housing system with a particular flow rate may not be the best answer.

Seeding is another unique consideration for the coating industry. While many pigments initially meet the size requirements to pass initial filtration, over time and through the process, flocculation of pigment particles can occur, creating small seed-like particles. While these may, again, break up and cause no problem, they can remain batched and compromise the integrity of the quality and smoothness of the coating.

At Filter Sciences, we understand the unique needs of each industry that relies on bag filtration and can recommend the best bag housing unit for your needs. And, if we don’t have what you need, our engineers can create one to meet your exact specifications. Contact us for a free quote today.

At Filter Sciences, we use top-quality materials and superior engineering processes to create the best filter bag housing systems available on the market. All of our units are assembled in the US and ready to ship. Contact us for your custom quote today.

Recent Posts

The Benefits of Filter Bag Housings in the Food and Beverage Industry (Part Two)

The food and beverage industry is highly dependent on filter bag housings and filtration to keep their products safe and palatable! In part one of this series, we broadly examined how food and beverage filtration play a role in food safety and food quality. In today’s post, we will explore more closely the specific industries…

The Benefits of Filter Bag Housings in the Food and Beverage Industry (Part One)

At Filter Sciences, we serve industries vital to our quality of life, including the food and beverage industry! The food and beverage industry makes modern living possible, and without it, we would be left spending our time just trying to survive. The filtration of food and beverages keeps our foods fresher, provides an ample shelf…

The Applications of Bag Filter Housings – Hydraulic Fracturing

Natural gas is the fossil fuel we all use that is a source of energy that make our daily lives more comfortable and time-efficient. From driving our cars and cooking meals, to heating our homes and providing electricity, it would be hard to go a day without it. Natural gas is formed from millions of…