Filter Bag Housing in the Metal Working Industry

Stainless Steel at Carbon Steel Pricing

In Stock | Next Business Day Shipping

Keeping Production at an All-Time High

Metalworking Fluid Filtration

Metalworking is a collective term that encapsulates several processes, each serving its own purpose to meet the demands of productivity and manufacturing. Machines are the driving force behind the metalworking industry and are used to provide rapid results. If there is a breakdown in the system, productivity is halted, costing time and efficiency.

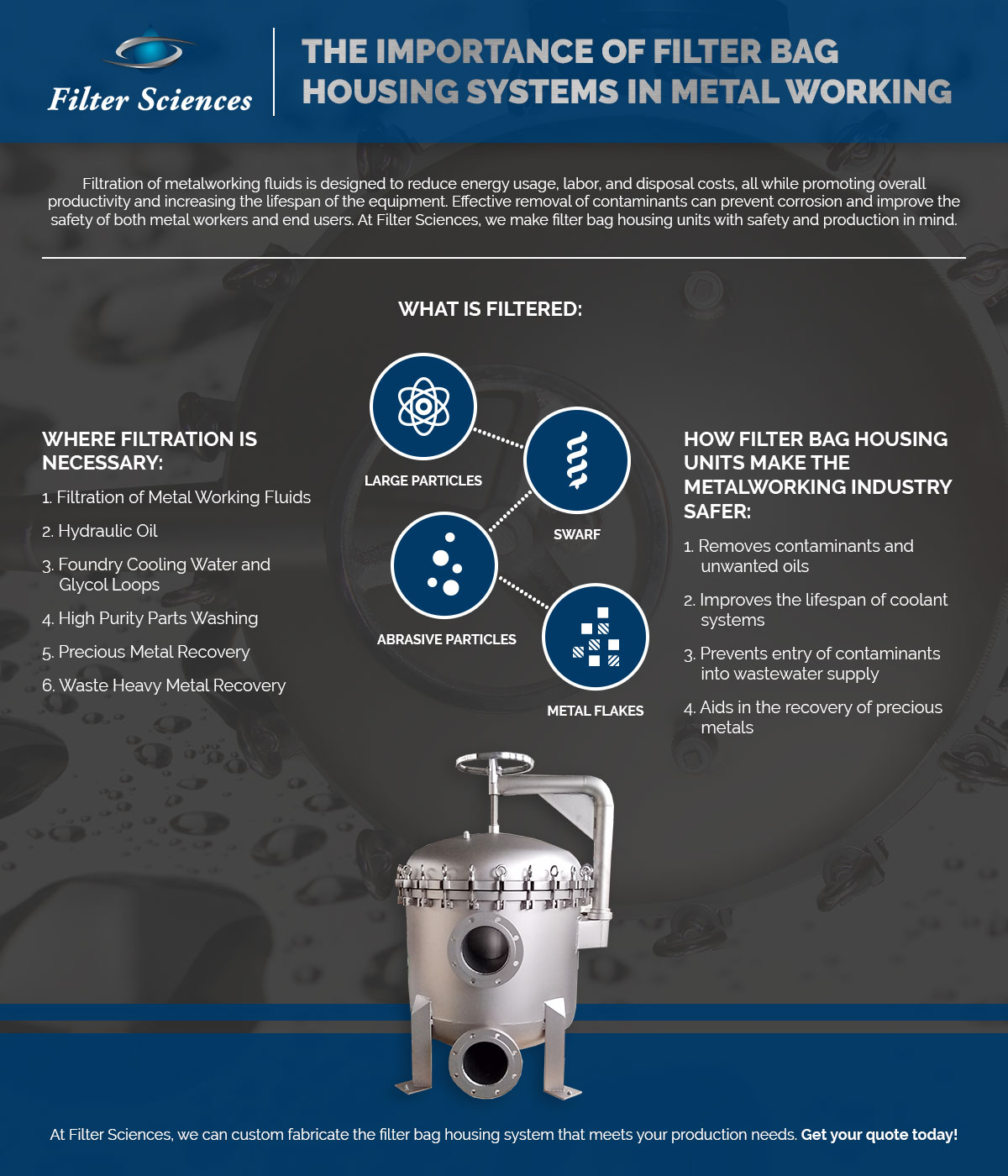

Metalworking fluids are those that facilitate the operation by reducing wear on machinery, keeping machinery cool, and washing parts, tools, and washing away impurities. To safely remove contaminants and oil from metalworking fluids for reuse or disposal, proper filtration is a critical part of safety and efficiency.

Filter bag housing units provide the framework for the filtration process and aid in contaminant removal. For metalworking fluids, hydraulic oil, foundry cooling water and glycol loops, high-purity washing parts, precious metal and waste heavy metal recovery, filter bag housing systems from Filter Sciences are what will help keep your systems operating.

Founded on Quality and Integrity, Backed by Science and Superior Engineering

When it comes to metalworking, there is no room for shortcuts that may compromise safety, productivity, and the quality of end products. At Filter Sciences, we use superior engineering practices to create filter bag housing units that support the machinery that fuels the metalworking industry. Our stainless steel filter bag housing units are available at carbon steel pricing and are assembled in the United States. Because we engineer and create all of our filter bag housing systems, if we do not have what you need in stock, we can custom engineer one to meet your specific regulatory and operational requirements. Contact us for your custom metalworking filtration quote today.

Recent Posts

Beer Filtration in the Brewing Industry

Filtration is key to improving the quality and taste of beer in any setting. Whether individuals are making homebrew, pub breweries are making stock quantities, or large-scale beverage distributors are mass producing a line of beer products, the filtration is very similar. In today’s post, we are going to review some of the steps of…

Bag Filtration Throughout The Industries

Bag filter housings are used in a wide number of industries and we’ll explore how one filtration system works uniquely and specifically in each industry. Many industrial filtration companies have a one size fits all approach, and while this is not inherently a negative thing, it leaves a lot of opportunities in the industry. It…

Why Use Flexible Filtration?

Flexible filter media is one component of bag filtration that makes industrial filtration possible and benefit the industries it serves. Industrial liquid filtration serves a myriad of industries from water treatment facilities and food and beverage to plastics and hydraulic fracturing. A highly durable and long-lasting filter bag housing unit is a vital component to…