Single Bag vs. Multi-Bag Housings: The Differences

When it comes to choosing the right equipment for your industrial needs, finding the best products and the most trustworthy companies to work with can be a top priority. However, getting what you need and ensuring that it’s cost-effective and lasts for years is another important factor. At Filter Sciences, we’re proud to offer top-quality…

Bag Filters FAQs

Here at Filter Sciences, we strive to provide only the highest quality, commercial-grade filtrations systems to remove particles and other contaminants from liquids to maintain safety and quality for our clients. One of the vital components of any industrial filtration system is the filter bag housing and the bag filter itself, which is used to…

When to Replace a Filter Bag?

Welcome to Filter Sciences, the industry leader in providing unparalleled filtration solutions for a wide range of industries. Our commitment to excellence and innovation has positioned us as the go-to choice for businesses seeking superior filtration performance. In this blog, we invite you to explore the remarkable features and benefits of Filter Sciences’ filter bags….

What Do Bag Filters Move?

Bag filters are an essential part of many industrial processes, providing effective filtration for a wide range of materials. But what exactly can bag filters move? In this guide, we’ll explore the capabilities of bag filters, how they work, and the benefits they offer. Filter Sciences is a leading provider of bag filters and…

What Is The Purpose Of A Bag Filter?

If you work in or own a large factory, oil & gas plant, chemical processing plant, or any other industry that deals with liquids, you know the importance of having a reliable filtration system in place. Filters not only keep water supplies safe, but they also refine and clarify production liquids like cooking oil and…

Grade 304 vs Grade 316 Stainless Steel Filter Housings

Filter Sciences stocks both grade 304 and grade 316 stainless steel filter housings in all single and multi-bag filter housing designs we offer. Grade 316 stainless steel offers some extra benefits that 304 stainless doesn’t, but it’s not necessary for every industry. Here’s a short guide of what to expect from grade 304 and grade…

What Makes Filter Sciences Filter Bags Special

When it comes to industrial filter bags, quality matters. That’s why Filter Sciences takes special care to ensure that our filter bags are designed to meet the highest standards in the industry. Their filter bags are designed to capture particles of all sizes from a variety of different sources for use in a variety of…

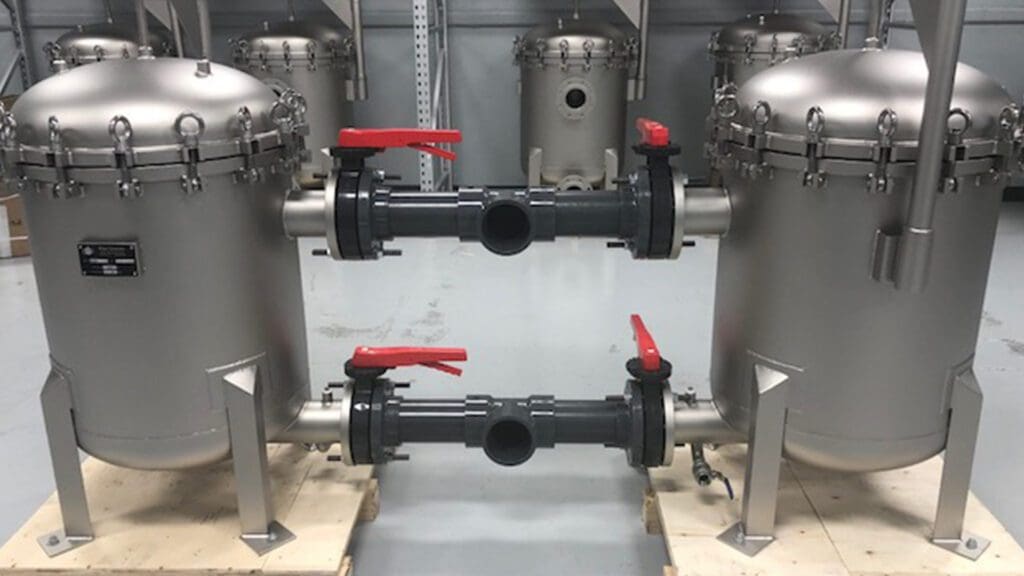

Different Types of Filter Bag Housings

Here at Filter Sciences, we’ve manufactured our filter housings to be as durable and adaptable as your filtration system needs. Filter bag housings are an important part of any filtration system. They provide secure and efficient containment for filter bags, allowing for the uninterrupted flow of fluid or air through the filter media. They are…

Why Use a Bag Filter in Your Industrial Setting?

Filtration is incredibly important to remove debris and other impurities from fluids that you need to use in an industrial setting. Filters like those produced by Filter Sciences are used in oil and gas, metalworking, pharmaceutical, food and beverage, and many more industries. Filter Sciences’ industrial bag filter housing units are designed to provide reliable…

Convenient Features of Filter Bag Housings

Filter bag housings are a convenient and efficient way to filter various liquids, including water, in industrial and commercial settings. The most common type of filter bag housing is the stainless steel filter housing, which is extremely durable and corrosion-resistant, making it ideal for a wide variety of applications. At Filter Sciences, we engineer both…

- « Previous

- 1

- 2

- 3

- Next »